PRODUCT INFORMATION

Serious racers are constantly pushing the envelope and everyone knows that shaving off .001’s of a second from their ET which translates into more win lights.

.

Ceramic hybrid bearings use ceramic balls and steel races. Ceramic balls weigh up to 40% less than steel balls, depending on size. This reduces centrifugal loading and skidding, so hybrid ceramic bearings can operate up to 50% faster than conventional bearings. This means that the outer race groove exerts less force inward against the ball as the bearing spins. This reduction in force reduces the friction and rolling resistance. The lighter ball allows the bearing to spin faster, and uses less energy to maintain its speed.

.

Ceramic silicon nitride balls exhibit much greater hardness than steel balls resulting in at least 10 times greater ball life due to the ability to hold the surface finish longer. The ball has dramatically smoother surface properties than the best steel ball resulting in less friction between the balls and bearing race surfaces. Thermal properties are also dramatically improved over steel balls resulting in less heat buildup at high speeds.

.

Ceramic has 35 percent less thermal expansion, 50 percent less thermal conductivity, are lighter weight and are non-corrosive.

.

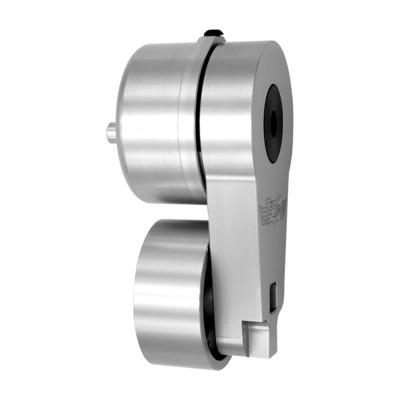

- Category: Tensioner

- Brand: Mopar

- Weight: 4 lbs

- Dimensions: 8 × 4 × 4 in

- Manufacturer: USA

- Material: Clear Anodized Billet

- Brand: Mopar

- Weight: 4 lbs

- Dimensions: 8 × 4 × 4 in

- Manufacturer: USA

- Material: Clear Anodized Billet

.

Upgrade your pulley to Ceramic Bearings!

-All of these tensioners/pulleys can be upgraded with ceramic bearings for an additional $75 per bearing.

.

Serious racers are constantly pushing the envelope and everyone knows that shaving off .001’s of a second from their ET which translates into more win lights.

Ceramic hybrid bearings use ceramic balls and steel races. Ceramic balls weigh up to 40% less than steel balls, depending on size. This reduces centrifugal loading and skidding, so hybrid ceramic bearings can operate up to 50% faster than conventional bearings. This means that the outer race groove exerts less force inward against the ball as the bearing spins. This reduction in force reduces the friction and rolling resistance. The lighter ball allows the bearing to spin faster, and uses less energy to maintain its speed.

Ceramic hybrid bearings use ceramic balls and steel races. Ceramic balls weigh up to 40% less than steel balls, depending on size. This reduces centrifugal loading and skidding, so hybrid ceramic bearings can operate up to 50% faster than conventional bearings. This means that the outer race groove exerts less force inward against the ball as the bearing spins. This reduction in force reduces the friction and rolling resistance. The lighter ball allows the bearing to spin faster, and uses less energy to maintain its speed.

.

Ceramic silicon nitride balls exhibit much greater hardness than steel balls resulting in at least 10 times greater ball life due to the ability to hold the surface finish longer. The ball has dramatically smoother surface properties than the best steel ball resulting in less friction between the balls and bearing race surfaces. Thermal properties are also dramatically improved over steel balls resulting in less heat buildup at high speeds. Ceramic has 35 percent less thermal expansion, 50 percent less thermal conductivity, are lighter weight and are non-corrosive.

.

-Part# ARS6500A

CUSTOMER REVIEWS